Throughout much of 2021 and into 2022, the electronics supply chain is going to suffer from various component shortages and unavailability of products. This is outside our control and we can only advise you of these issues as and when they arise and try to help to cross refer the parts if this is an option.

As a knock-on effect to the reduction in availability is the fact that suppliers with stock are increasing their prices often daily. They have the upper hand!

View the BBC article about “chippageddon” here.

At the end of this article we have appended some genuine experiences all in the last month or so. PLEASE DO read them to see what we are all up against!

Why is there an electronic component shortage?

Global tech innovation boom:

BBC 17th March – The semiconductor shortage began last year, as the pandemic hit. Suffering from poor sales, car manufacturers cut their orders from the Chinese factories making computer chips. In response, the chip supply from factories was transferred to other sectors that had high demands.

And unable to retrieve cancelled orders when demand for cars grew, Volkswagen, Honda, Toyota and General Motors all had to reduce production.

Meanwhile, as technology sales boomed, with people staying at home, other sectors were also affected.

As innovation in technology continues, so does the demand for more sophisticated electronic devices. Smart technology is becoming ever more complex – from smart watches, to home assistants, to A1 features. On top of this, existing smartphone technologies are constantly evolving, requiring more complex and intricate designs and a larger volume of electronic components.

Electric cars are becoming increasingly popular, and 2021 is predicted to be the year that the industry booms. However, the automotive industry requires a large volume of electronic components for manufacture, and this high demand is contributing to a global shortage.

And there is currently a shortage of cobalt, used for batteries, because China has exercised a monopoly over the cobalt supply.

Tariffs on aluminium and steel:

The US government placed trade tariffs on aluminium and steel. Since nearly every industry relies on electronic components for manufacturing, this has caused issues and concerns worldwide.

Long Story Short

The pandemic has significantly reduced market capacity for electronics components. The pandemic’s epicentre—Wuhan, China—is home to many electronic and mechanical suppliers, so when the area went on lockdown and factories could not produce at full capacity or at all, there was not enough supply to meet demand.

As the coronavirus spread around the world, so did the components shortages and this will continue throughout 2021 and well into 2022. Factories in Malaysia, the Philippines, and Indonesia cannot cope with the current demand & delays in production & shipping is further compounding these issues. As a result, OEMs worldwide cannot control the supply chain and this leads to an inability to manufacture their own products.

BBC – 23rd April – Jaguar Land Rover (JLR) is shutting its two main car factories temporarily due to a shortage of computer chips.

The difficulties at Britain’s biggest carmaker echo similar problems at other manufacturers, including Ford, who have been hit by a global shortage of chips.

The Covid-19 pandemic has driven up demand for semiconductor chips for use in electronics such as computers, as people worked from home, and suppliers are struggling to adjust.

There has also been a fire at a Japanese company, part of Renesas Electronics, one of the world’s biggest makers of semiconductors for the car industry.

Also on Thursday, France’s Renault warned that the chip shortage was worsening. On Wednesday, carmaker Stellantis, which owns the UK Vauxhall brand, said it would replace digital speedometers with more old-fashioned analogue ones in one of its Peugeot models, as the fallout continues.

Samsung, the world’s biggest computer-chip manufacturer, has warned of a “serious imbalance” in the semiconductor industry, as global shortages cause disruption.

If a multi-national company like JLR cannot secure their requirements what chance have we got?

What can we do?

- Once you have your quote place your order as soon as possible to try to avoid component shortages and price hikes. We can no longer guarantee prices – even overnight they can change.

- Plan well in advance. Place orders now for PCB’s that are required within the next 12-month so that we can secure parts to try and meet your demand.

- Consider which components might go obsolete and depending upon the quantity and pricing UK Electronics will buy those in immediately and use them on your boards over the next 12 months.

- Respond immediately to any cross refer recommendations we might make.

And if you are not already a UK Electronics customer – why not?

As UK:E is primarily a contract manufacturer, we have extensive experience of supporting customers who are looking to get their products to the market. In addition to our core electronics manufacturing business, we have an array of services to support Research and Development – helping our clients to realise their designs early.

We have a state-of-the-art manufacturing facility and are able to quote for a variety of work – from low volume specialist instruments to large volume consumer applications, including full box build.

If you require any other aspects of our manufacturing or R&D services, then please speak with a member of our sales team at:-

Here are some recent examples: –

Power Relays

We had been buying these off the shelf direct from Panasonic for the last 5 years in batches of 100-500pc.

We placed 2 orders in April.

1 order they have managed to secure stock.

The second we are waiting for some delivery confirmation.

Panasonics system date is now showing 86 weeks lead-time.

This is a microprocessor

We regularly bought it for $6.15. In the space of ONE DAY it went from $15 to $25!

From: Sophia –

Sent: 14 April 2021 08:05

To: Dave Walker <Dave.Walker@ukelectronics.co.uk>

Cc: sales>

Subject: Re: RE: QUOTATION PLEASE

Hi Dave,

I know, but the website stock is not our own stock, we just share our supplier’s stock, they increased the price, we have no choice here. Cause we cannot sell it under the cost. Hope you can understand it. If it’s our own stock, we definitely will support you at old price, but we don’t.

Brexit “paperwork” charge

From: Richard

Sent: 07 April 2021 09:13

To: Michelle Townson <Michelle.Townson@ukelectronics.co.uk>

Subject: FW: QUOTE REQUEST – OUR REFERENCE UKE 5361

Hi Michelle,

Thanks for the email. The price for 135pcs is £38.11each

Carriage would be £22.90 per shipment and there is also an additional customs preparation charge due to the new Brexit paperwork for shipments over €1,000 which is £25.98 per shipment.

Lead time from the factory build would be approx. 10 weeks, but I would advise placing an order as soon as you can to secure stock.

PCB’s

The bare PCB industry, based mainly in China, is also struggling with increases in Copper prices and availability.

We have been advised that there will be price increases across the whole supply chain. This is especially the case for non-standard and high copper weight FR4 laminates.

In addition to PCB cost, lead-time has also increased for all FR4 products as companies in China are trying to bulk buy as much of the material as possible before prices rise even higher. (Continued)

As an example – A standard double sided FR4 laminate sheet was 130RMB in 2019 but is now up to 220RMB in 2021, which is an increase of 70-80%

In terms of PCB price increase, this is ranging between 6 – 28% from prices seen in 2020.

In terms of lead-time increase – this is ranging between 3 – 8 weeks!

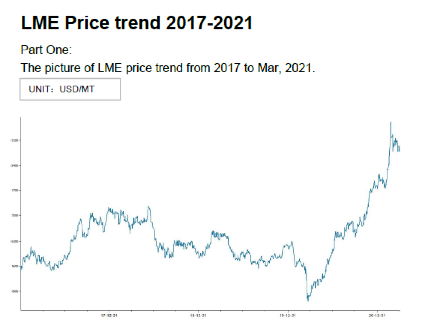

The graph below displays how erratic laminate prices have been since 2017.

A huge upward trend can be seen since the end of 2020.

To avoid significant price increases on your products and lead-time problems, please continue to send in any and all enquiries / orders as soon as possible, to ensure we can get these placed and worked on with immediate effect.

You can contact our team on: sales@ukelectronics.co.uk

PCB Design

PCB Design  Electronic Assembly

Electronic Assembly  PCB Prototyping

PCB Prototyping  EMC Testing

EMC Testing  Box Build

Box Build  Cable Assembly

Cable Assembly